Anti-Foam Control Solutions-- Advanced Solutions for Foam Avoidance and Control

Anti-Foam Control Solutions-- Advanced Solutions for Foam Avoidance and Control

Blog Article

Finest Practices for Choosing the Right Anti-Foam Control Remedy for Your Requirements

Choosing an efficient anti-foam control option requires a thorough examination of your distinct operational needs. Key factors to consider consist of the specific residential or commercial properties of your procedure, such as temperature, pH, and chemical interactions, every one of which significantly affect the performance of defoaming representatives. Moreover, ensuring compatibility with the medium and sticking to regulative standards are important for successful execution. As we check out these crucial variables, it becomes obvious that the right choices can lead to not only instant advantages but additionally long-term functional improvements that necessitate further evaluation.

Understand Your Foam Problem

Frequently, companies come across foam-related problems that can prevent operational efficiency and item top quality. Foam development can occur during different procedures, including mixing, fermenting, and transport, and it frequently leads to devices inefficiencies, manufacturing downtime, and enhanced operational costs. Recognizing the underlying sources of foam generation is essential for attending to the trouble effectively.

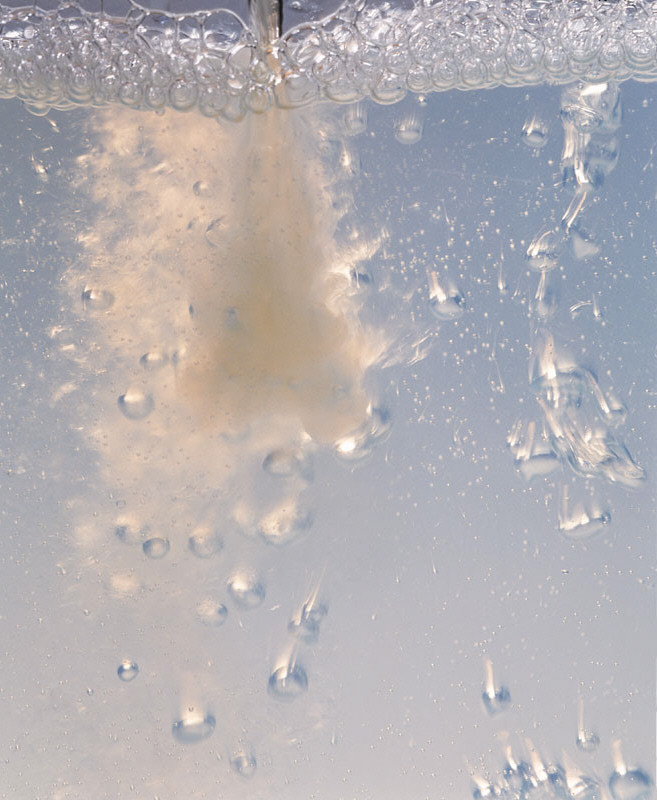

Foam can occur from several variables, such as the nature of the products entailed, agitation degrees, temperature level variations, and chemical responses. Specific surfactants can worsen lathering, while high shear mixing can introduce air, leading to unwanted foam accumulation. Additionally, ecological conditions and the certain features of the liquid systems being used can significantly influence foam behavior.

By evaluating these variables, organizations can obtain insights right into their foam concerns, allowing them to create targeted approaches to mitigate foam formation and enhance overall procedure efficiency. This fundamental understanding is vital for selecting an appropriate anti-foam control service tailored to details functional needs.

Assess Anti-Foam Options

When taking into consideration anti-foam choices, it is essential to thoroughly review the numerous formulations offered on the market to locate the most ideal option for your certain foam-related challenges. Anti-foam agents come in varied kinds, including silicone-based, non-silicone, and natural formulations, each offering distinct buildings and performance attributes.

Begin by analyzing the particular application requirements, such as temperature level thresholds, pH levels, and the sort of foam being created. For example, silicone-based representatives are understood for their effectiveness in high-temperature settings, while non-silicone alternatives might be more effective in food processing applications as a result of regulative considerations.

It is additionally critical to take into consideration the price of application and the wanted longevity of the foam control. Some formulations may give prompt defoaming activity, while others supply long term stability. Performing small examinations can provide understandings right into the performance of each option in real-world conditions.

Consider Application Compatibility

In the world of anti-foam options, guaranteeing application compatibility is vital for attaining optimum performance. The efficiency of an anti-foam representative mostly relies on its ability to work sympathetically within the details criteria of your application, consisting of temperature, pH, and the existence of other chemicals. Various formulations might perform variably across varied problems, thus extensive screening is important.

Begin by determining the pop over to these guys features of your process, such as viscosity and the nature of the medium in which the anti-foam will be utilized. For example, some hop over to these guys anti-foam representatives may function well in aqueous remedies yet fail in organic solvents. In addition, think about the potential interactions with existing ingredients and materials to stay clear of undesirable effects.

It is additionally essential to review the method of application. Whether the anti-foam is introduced constantly or batch-wise can influence its efficiency and durability in the system. Guarantee that the chosen item is not only compatible with the functional specifications but likewise lines up with any kind of regulative requirements essential to your market.

Assess Environmental Impact

How does the ecological impact of an anti-foam control remedy affect your overall choice process? The eco-friendly footprint of your picked anti-foam representative is critical, as it shows your commitment to sustainability and governing compliance. Picking an site here item with minimal environmental consequences can boost your company image and foster customer count on.

When evaluating ecological influence, take into consideration the biodegradability of the anti-foam solution. Biodegradable choices are normally better, as they damage down extra rapidly and reduce long-term ecological damage. Furthermore, review the capacity for bioaccumulation and poisoning to aquatic life. Solutions with high poisoning can posture substantial threats to neighborhood ecosystems, possibly causing governing fines and ecological deterioration.

An additional vital aspect is the presence of hazardous compounds. Anti-foams consisting of hazardous chemicals may require special handling and disposal measures, making complex and enhancing functional expenses compliance with ecological guidelines. Picking environment-friendly alternatives can minimize these dangers.

Monitor and Enhance Performance

To optimize the efficiency of your anti-foam control remedy, it is important to consistently check and enhance its efficiency. Constant analysis enables the recognition of any inconsistencies in foam degrees and the succeeding performance of the anti-foam representative.

Carry out a methodical method to check essential efficiency indicators (KPIs), such as foam volume, stability, and the reaction time of the anti-foam agent. Use logical tools and methods, such as aesthetic inspections, foam height dimensions, and specialized sensing units, to gather precise data.

Additionally, preserve open communication with vendors for technical assistance and understandings on the current innovations in anti-foam modern technology. This positive technique not only help in accomplishing optimal performance yet also lessens operational interruptions and boosts overall process effectiveness. Routinely taking another look at and improving your anti-foam method guarantees that you are effectively handling foam-related obstacles, ultimately resulting in enhanced performance and cost savings.

Verdict

In final thought, selecting the appropriate anti-foam control solution necessitates a thorough assessment of specific application requirements, including temperature level, pH levels, and chemical compatibility. Extensive testing for instant and prolonged defoaming effectiveness is crucial, as is factor to consider of ecological effects and governing compliance. By focusing on environmentally friendly alternatives and continuously keeping an eye on performance, operational efficiency can be boosted while properly alleviating foam-related difficulties. Abiding by these finest techniques will help with enlightened decision-making in anti-foam control solutions.

Picking an effective anti-foam control service requires a detailed examination of your unique functional needs.In the world of anti-foam solutions, ensuring application compatibility is vital for accomplishing ideal efficiency.Just how does the ecological influence of an anti-foam control solution influence your overall selection process?In conclusion, selecting the appropriate anti-foam control solution necessitates an extensive assessment of certain application requirements, consisting of temperature, pH levels, and chemical compatibility (Anti-Foam Control Solutions). Sticking to these ideal techniques will certainly assist in educated decision-making in anti-foam control services

Report this page